How is the manufacturing landscape going to look like in the near future? In a few words, the trends in manufacturing industry will evolve in three major areas: implementing recent technological advancements (Industry 4.0 and 5.0), finding ways to address post-pandemic challenges, and meeting sustainability requirements. Let’s do a deep dive into how the manufacturing trends are going to transform the industry in 2026.

Key Takeaways:

- Digital transformation remains a top priority among manufacturing industry trends, enabling manufacturers to improve efficiency, resilience, and competitiveness.

- Agentic AI is emerging as a critical enabler of automation, optimization, and smarter decision making.

- Ongoing challenges like supply chain issues and talent shortages will persist in 2026.

- The adoption of smart materials is accelerating; it allows manufacturers to develop lighter, stronger, and cost-effective products.

- Sustainability initiatives are gaining momentum and become included in long-term strategies.

Latest Trends in the Manufacturing Industry

Addressing talent challenges

Despite the increased automation, most industries are still facing talent challenges, and manufacturing is no exception. An aging workforce, a lack of skilled workers, competition for the digital workforce with other industries, and difficulties in retaining talent—these are just some of the challenges for manufacturers, which they have been facing for several years and which are going to remain in 2026. Active implementation of technologies will amplify the talent challenges, as manufacturing companies increasingly need people who can work with innovative equipment and software. Of course, these challenges cannot but affect manufacturing production planning and timely product delivery,

Manufacturers have made some progress in tackling talent issues and attracting and retaining talent, for example, they started to offer flexible scheduling to workers and reward them. Here are the measures manufacturing companies are taking to address talent shortages:

- Leveraging digital tools for more effective workforce planning and management (e.g., AI-driven applications).

- Upskilling the existing employees and establishing relationships with educational institutions to provide students with the required skills.

- Tapping into retirees’ expertise to impart their knowledge to the young workers.

- Taking a holistic skill-based approach to talent management.

In 2026, the main factors contributing to workforce issues are economic uncertainty, shifting trade conditions, and reshoring efforts. According to Deloitte’s forecast, here are the measures that are expected to change the situation in the coming year:

- Adopting flexible workforce models. For example, “build, buy, or borrow” framework includes investing in core talent, recruiting external personnel if it’s impossible to build required capabilities internally, or hiring temporary workers.

- Leveraging agentic AI to improve talent sourcing, screening, onboarding, and training efficiency.

In addition, as the talent shortages aren’t addressed quickly enough, the manufacturing sector is going to face one more challenge—delivering increased output with a decreased workforce. This requires manufacturing organizations to review their processes, increase work efficiency, and support available employees in upskilling and bridging their skill gaps. Therefore, addressing talent challenges will maintain its position among current manufacturing trends in 2026.

Read more: What Is a Resource Management Solution and Why Do You Need One? (Questions and Answers)

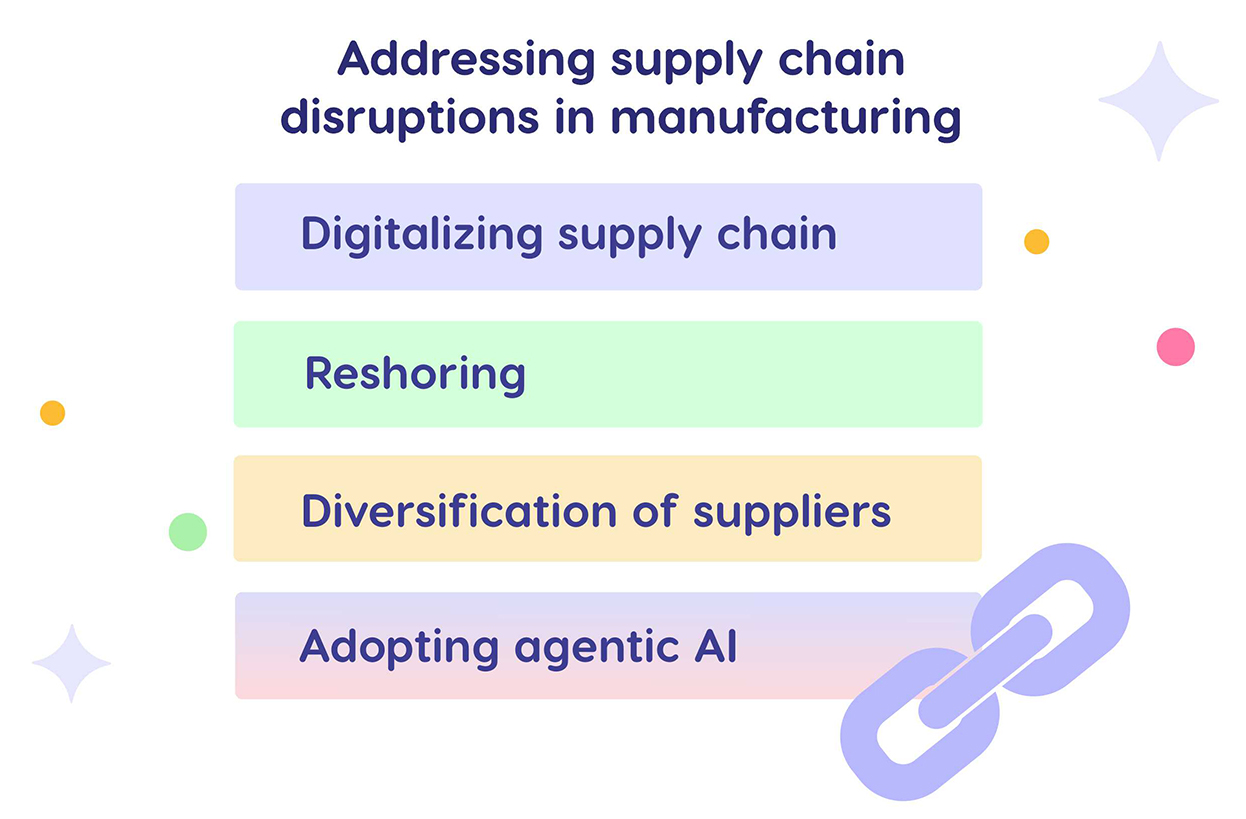

Navigating supply chain disruptions

Supply chain issues have been affecting industries since the start of the pandemic. In 2026, these manufacturing industry challenges are expected to continue, which is explained by factors like rising costs for raw materials, workforce shortages, shipping delays resulting from geopolitical tension, etc. [1]

Today, organizations have found some ways to overcome these challenges, and the situation is gradually getting better. However, there’s still a lot to be done to return it to the pre-pandemic level, especially with regard to the current geopolitical tensions. In 2026, manufacturers will continue their efforts for stabilizing supply chains, which means that addressing supply chain issues will maintain its position among future trends in manufacturing industry. Companies are expected to focus on the following processes.

Digitalizing the supply chain

Digitalization of the entire supply chain makes it an integrated ecosystem that is visible to all stakeholders—from suppliers to customers. This allows for achieving better visibility across the whole value chain and in such a way reduces risks, minimizes lead time, optimizes decision-making, and increases the supply chain resilience. For example, a manufacturer can create a digital twin of the supply chain to simulate diverse scenarios and get prepared for them.

Reshoring

The other way to achieve supply chain resilience is reshoring, e.g., relocating manufacturing facilities to an organization’s home country. This practice provides companies with numerous benefits:

- It saves time and costs for transportation;

- It optimizes quality control;

- It reduces lead time and time to market;

- It creates job opportunities for local people.

As a result, this increases supply chain resilience and decreases its dependence on global issues, so this industrial manufacturing trend is expected to continue in 2025 and beyond.

Diversification of suppliers

This proactive approach involves broadening a network of suppliers. This reduces dependence on a single supplier and promotes supply chain flexibility and resilience under conditions of various disruptions. Also, this approach contributes to achieving sustainability goals in some cases: e.g., when manufacturers choose local suppliers and reduce transportation-related carbon emissions.

Adopting agentic AI

In 2026, using agentic AI takes supply chain management to the next level. The technology enhances visibility, helps mitigate risks and optimize costs. Here are some examples of agentic AI capabilities:

- Monitoring potential disruption sources;

- Warning personnel of potential issues;

- Quantifying the potential impact;

- Giving recommendations on balancing risks and costs;

- Initiating mitigation measures.

As we see, tools like agentic AI become increasingly critical for manufacturing companies seeking to optimize operations, overcoming challenges, and gaining competitive advantage.

Sustainability and related challenges

Sustainability is one of the recent trends in manufacturing that is expected to remain relevant in 2026 and beyond—there are numerous legal requirements to reduce environmental impact in all industries, and manufacturing plays a pivotal role in meeting them. Green manufacturing involves reducing waste and environmental pollution, using recycled materials and renewable energy, etc. As a result, manufacturing companies are increasingly investing in green initiatives.

At the same time, manufacturers face a number of challenges and risks related to implementing green initiatives, which will remain until the period of transition to green manufacturing is finished. These challenges include:

- Technical readiness for green manufacturing;

- Higher production costs;

- Customers’ readiness to use other materials and pay more;

- Managing the batteries’ lifecycle.

In 2026, manufacturers are expected to continue making efforts to address the above-mentioned challenges and succeed in implementing green initiatives (e.g., they can partner with external organizations providing sustainability solutions, look for renewable fuel technologies, invest in electrification, etc.). For example, the survey by the UK Manufacturer’s Organisation reveals that 8 out of 10 manufacturing companies are embedding “green” strategies in their business plans for the next 5 years.

In addition, industrial companies will continue working on electrification and reducing carbon footprint of their products, which is confirmed by the results of Deloitte’s investor reports. [1]

Finally, achieving sustainability will be impossible without leveraging the so-called green software—the tools that help reduce waste, optimize energy consumption, and reduce the environmental impact of manufacturing facilities. So, in 2026 and beyond, manufacturers will integrate software tools that help them meet sustainability requirements (reducing waste, achieving energy efficiency and carbon neutrality) and continue following manufacturing sustainability trends [2].

Providing aftermarket services

Though this isn’t a new trend in manufacturing industry, it has become increasingly common for manufacturers to offer aftermarket services in recent years. This is also related to the more common use of advanced technologies, e.g., sensors, AI, IoT, virtual and augmented reality, machine learning, etc. These services range from supplying spare parts to AR-based troubleshooting assistance. Providing aftermarket services gives manufacturers numerous benefits, for example:

- It creates opportunities for generating revenue;

- It gives companies a competitive advantage;

- It contributes to customers’ loyalty.

We expect this tendency to remain among the latest trends in manufacturing for 2026 and beyond. The above-mentioned Deloitte’s Outlook states that in the upcoming year, this trend will be marked by increased use of agentic AI to help companies implement proactive planning, reduce response time, and minimize customers’ downtime.

Decentralized manufacturing

Currently, manufacturing companies are striving to address the challenges caused by ongoing geopolitical tensions, supply chain volatility, and sustainability requirements. Decentralized manufacturing is one of the means to respond to these challenges. It involves running manufacturing processes in multiple smaller facilities instead of one entity, wide use of technologies (AI, IoT, 3D printing), and adaptability to local markets. The role of 3D printing should be mentioned separately: it allows production companies to produce goods faster and in smaller batches, which makes this technology indispensable for decentralized manufacturing.

Therefore, this manufacturing approach helps reduce transportation costs, reduce their dependence on supply chains, and accelerate products’ time-to-market. In the future, we expect this trend to develop—production processes will be more frequently run at a network of interconnected facilities rather than centralized.

Let’s now consider recent trends in manufacturing technology and how manufacturing companies can benefit from them.

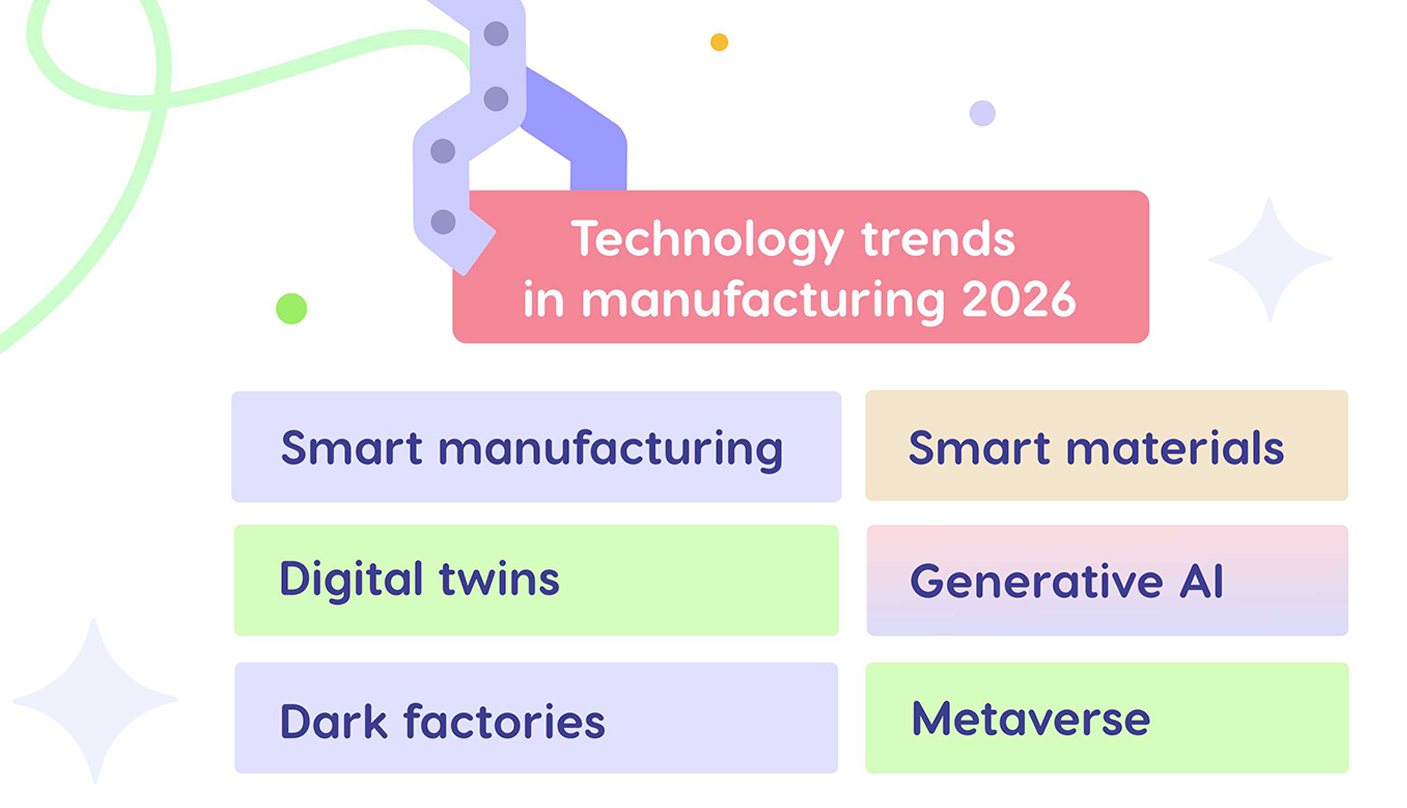

Technology Trends in Manufacturing

Smart manufacturing trends

Under current conditions of economic turbulence, workforce shortage, and supply chain disruptions, manufacturing organizations should work towards increasing the efficiency of their operations, achieving business agility and resilience. This is why they are actively implementing the concept of smart factories that integrate data, sensors, and the latest technologies (AI, IoT, 5G, data analytics) in the production process. Here are some of the examples of advanced manufacturing technologies companies employ:

- AI assists in performing complex tasks, enhancing decision-making, forecasting equipment failure, ensuring quality control, and more.

- additive manufacturing allows for rapid prototyping, maintenance and repair as well as creating objects on demand, which reduces production time and dependence on the supply chain.

- The Industrial Internet of Things makes it possible to collect data from machines and other connected objects to analyze their conditions and performance.

- Collaborative robots (cobots) work together with people and can learn to perform new operations.

- Augmented and virtual reality solutions allow manufacturers to monitor and control the production process without the need to be on-site.

Smart factories provide organizations with numerous benefits—they increase productivity and efficiency by optimizing processes, help reduce costs, provide end-to-end visibility of manufacturing operations, and support sustainability. [4]

In 2026, manufacturing companies will continue investing in smart manufacturing, including agentic AI and robots. [7]

Smart materials

Manufacturers cannot thrive on technologies alone; the materials used for production processes are also evolving into smart materials. These materials can sense changes in the environment and respond to them in a predictable way. In contrast to traditional materials, they don’t remain passive but change their properties in response to different stimuli: temperature, pressure, light, etc. For example, they can change their shape, regulate heat or vibration, and even heal small cracks. The smart materials market is expected to grow annually by 8%, which means that this trend is here to stay among new trends in manufacturing industry for 2026 and beyond.

Digital twins

Digital twins are expected to continue to revolutionize the manufacturing industry in 2025. This technology allows for creating a digital copy of the actual environment, which makes it possible to run simulations and find more effective ways to run manufacturing processes. Digital twin provides manufacturers with the following benefits and opportunities:

- It improves the design of the manufactured products;

- It optimizes production efficiency;

- It accelerates products’ time to market;

- It allows manufacturers to predict potential issues in the production process;

- It contributes to reducing material waste and optimizing energy consumption;

- It can optimize supply chain management.

Therefore, leveraging digital twins allows manufacturers to optimize their operations, contribute to sustainability, improve decision-making, and optimize manufacturing costs, which means that this technology trend is here to stay for 2026 and beyond. [5]

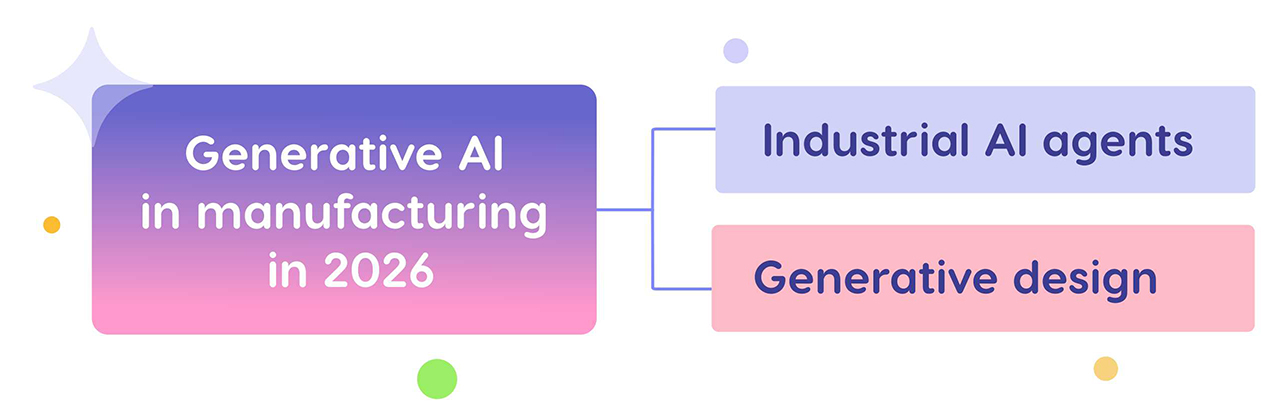

Generative AI

Generative AI is gaining momentum across industries and has become one of the manufacturing technology trends. As shown by the survey conducted by Deloitte [1], in 2025, more than 55% of manufacturing companies already leveraged generative AI, and about 40% were planning to increase investments in this technology in the coming years. Also, manufacturing companies have become increasingly focused on data quality to take advantage of generative AI.

What are the areas of gen AI applications in manufacturing? First, it has the potential to improve product design. For example, manufacturers can use the technology to produce lighter and stronger components or optimize the use of available materials. Also, gen AI can be used to improve customer experience with chatbots and support systems. [3] Let’s look at the most recent advancements in the application of generative AI for the upcoming years.

Industrial AI agents

These agents are new manufacturing technology that is expected to revolutionize the industry in 2026 and beyond. From analyzing data and generating insights they proceed to taking action. This means that manufacturing companies can plan, execute, and oversee their operations with minimal human intervention. Industrial AI agents will coordinate complex workflows from start to finish, make decisions, manage inventories and production processes most efficiently and effectively. Taking all these benefits into account, the percentage of manufacturing companies adopting AI agents is expected to grow from 6% to 24% by 2027. [7]

Generative design

Generative AI will also revolutionize the design processes. Generative design means that you can feed a generative AI tool with all specifications, targets, material requirements, and constraints for a new product and get a complete design blueprint. In 2026, we’re going to see its active use in real-life production processes. This technology has already been used: for example, Jacobs optimized the design of the life-support backpack used by NASA astronauts, balancing its weight, safety, and reliability.

Read more: AI in Project Management: Is the Future Already Here?

Dark factories

This is one of the relatively new trends in manufacturing. These factories are fully automated industrial facilities that manufacture products with minimal or without any human intervention. This approach is also called “lights-out manufacturing”, as they require no lighting for work. As these factories are fully automated, can operate 24/7, and you can find robots, AI, and advanced automation systems instead of people. What are the benefits of this approach to manufacturing?

- High efficiency (robots don’t get tired and don’t need to take breaks);

- Reducing labor costs;

- Increased safety: there are no risks for human workers when working on dangerous tasks;

- Improved product quality: there’s no possibility for human errors and no need to address their consequences.

An example of this factory is Xiaomi’s fully automated smart factory which is capable of producing 10 million smartphones a year. Despite the existing challenges these factories may face (high investments, cyber risks, costly maintenance, etc.), this manufacturing trend is expected to become more common in 2026 and beyond

Metaverse

Metaverse is one of the latest trends in manufacturing technology. It involves leveraging cutting-edge technologies like extended reality, digital twins, AI, IoT, and collaborative environments to enable interaction between the physical and digital worlds, and thereby optimize manufacturing processes. The technology is applied to the following areas of manufacturing:

- Design and prototyping;

- Workforce development and training;

- Optimization of manufacturing processes;

- Predictive maintenance;

- Optimizing supply chains.

Metaverse in manufacturing can reduce costs for prototyping, improve collaboration between teams, enhance decision-making, and increase manufacturing companies’ agility and flexibility. So, this manufacturing technology trend is here to stay in 2026 and become more widespread.

These technologies are shaping the present and the future of manufacturing industry. Therefore, manufacturers are expected to increase their investments in digital technologies and smart materials that will help them improve operational efficiency, address workforce issues and geopolitical uncertainty, and provide them with growth opportunities. So, these IT trends in manufacturing will persist in 2026.

As manufacturing operations become more and more complex, digital tools are becoming crucial for managing projects and resources effectively. Platforms like Epicflow leverage AI-driven capabilities and real-time analytics to help manufacturers prioritize projects, optimize workforce allocation, and overcome challenges and uncertainty. The solution leverages a value-driven approach to portfolio management, which allows organizations to deliver maximum value with available resources and overcome the complexity of demanding project environments. Contact us to discover how Epicflow can help your organization implement the latest trends in manufacturing industry, improve resource utilization, and gain a competitive advantage.

Conclusion

Future trends in manufacturing industry won’t differ dramatically from last years’ tendencies—most of them are expected to remain and evolve this year. First of all, digital transformation in manufacturing is expected to continue, including leveraging the latest technological advancements; it will help them gain a competitive advantage and address current challenges. Also, the industry is going to navigate the challenges caused by supply chain disruption and employee attrition. Finally, sustainability initiatives are expected to gain momentum this year—manufacturers are going to implement more and more initiatives aimed at decarbonization and electrification.

Manufacturing project management software is the right solution aimed to help you complete your production projects successfully despite all the ongoing challenges and take advantage of opportunities and trends.

Frequently Asked Questions

What will be the future of manufacturing?

The future of manufacturing will be be shaped by increased automation, use of AI and advanced technologies, sustainability and green manufacturing, industrial automation trends like metaverse, collaboration of people and machines.

Is AI the future of manufacturing?

Yes, AI will revolutionize the manufacturing industry and provide it with unprecedented opportunities. Here are some examples:

- AI is used in smart factories where machines require no human intervention.

- AI-driven predictive maintenance helps predict when equipment failure may occur so that manufacturers can avoid unexpected breakdowns and delays.

- Collaborative robots powered by AI increase the productivity of employees and the efficiency of manufacturing processes.

Despite the fact that AI will be a major driver of manufacturing processes, the technology won’t replace people.

What are technology trends in manufacturing?

The technology trends in manufacturing industry include the use of smart factories, artificial intelligence, Industrial Internet of Things, 3D printing, advanced materials, collaborative robots, augmented and virtual reality.

What are smart materials and how are they used?

Smart materials adapt to environmental changes (e.g., changes in temperature, light, pressure, etc.). They help create lighter, stronger, and more cost-effective products.

How can manufacturers manage workforce challenges?

For years, talent shortages remain one of the essential industrial manufacturing trends. Companies can invest in core talent, hire experts, use temporary labor, and leverage AI for skill-based workforce planning and accelerated training.

How does manufacturing projects management software help manufacturers?

Technology in manufacturing also affects how projects are managed. Manufacturing project management software like Epicflow provides AI-driven portfolio and resource optimization, real-time visibility, value-based prioritization, and intelligent resource allocation to help manufacturers cope with uncertainty, streamline workflow, and optimize the utilization of available resources

References

- 2025 Manufacturing Industry Outlook. Deloitte. Retrieved from: https://www2.deloitte.com/us/en/insights/industry/manufacturing/manufacturing-industry-outlook.html

- Dimitrov, D. (2024). The Future of Manufacturing: Technology Trends for 2025 and Beyond. Forbes. Retrieved from: https://www.forbes.com/councils/forbestechcouncil/2024/11/14/the-future-of-manufacturing-technology-trends-for-2025-and-beyond/

- Marr, B. (2024). 8 Game-Changing Manufacturing Trends That Will Define 2025. Forbes. Retrieved from: https://www.forbes.com/sites/bernardmarr/2024/12/06/8-game-changing-manufacturing-trends-that-will-define-2025/

- Top 10 Manufacturing Trends for 2025. Retrieved from: https://www.advancedtech.com/blog/manufacturing-trends/

- Trends for the Advanced Manufacturing Sector in 2025. Retrieved from: https://www.cecimo.eu/publications/trends-for-the-advanced-manufacturing-sector-in-2025/

- 2026 Manufacturing Industry Outlook. Deloitte Research Center for Energy and Industrials. Retrieved from: https://www.deloitte.com/us/en/insights/industry/manufacturing-industrial-products/manufacturing-industry-outlook.html#smart-manufacturing

- Marr, B. (2025). 6 Defining Manufacturing Trends Of 2026. Retrieved from: https://www.forbes.com/sites/bernardmarr/2025/11/12/6-defining-manufacturing-trends-of-2026/