Delivering projects for the sake of projects is no longer enough for business organizations these days. Every project executed should deliver value to the end customer and the organization.

Value engineering is a methodology that helps project leaders maximize the value of projects they are working on and optimize their costs. This approach is especially vital for complex projects and multi-project environments with a limited resource pool.

Read the article to explore the goals and benefits of value engineering, its key steps, possible challenges, and useful recommendations that will turn project work into measurable results.

What Is Value Engineering in Project Management?

Initially, the concept of value engineering didn’t belong to project management. It came from industrial engineering and manufacturing. In 1940, General Electric faced material shortages that forced its engineers to look for alternatives that could perform the same function at a lower cost. In 1970, as project management became more and more common and mature, VE started to be applied in this discipline as a systematic methodology for reducing cost and improving efficiency.

Before we define value engineering in project management, let’s first figure out what value is for PM. Value is a measurable benefit that a project generates to stakeholders in relation to resources invested. It’s not just the project output itself, but the benefits this output provides. For example, when a hospital invests in a project to develop a digital patient records system, the output of the project will be the new software, and the value – reduced waiting times and better patient care.

Finally, we’ve approached the value engineering definition for project management. It is a purposeful approach that involves increasing the value of a project outcome (a product, service, or process): optimizing the quality and at the same taking measures to optimize project costs. These measures involve simplifying the design, finding cheaper alternatives for materials, resource optimization, reducing lead time, etc. So, in simple words, value engineering in project management is about delivering the biggest value at minimum possible cost.

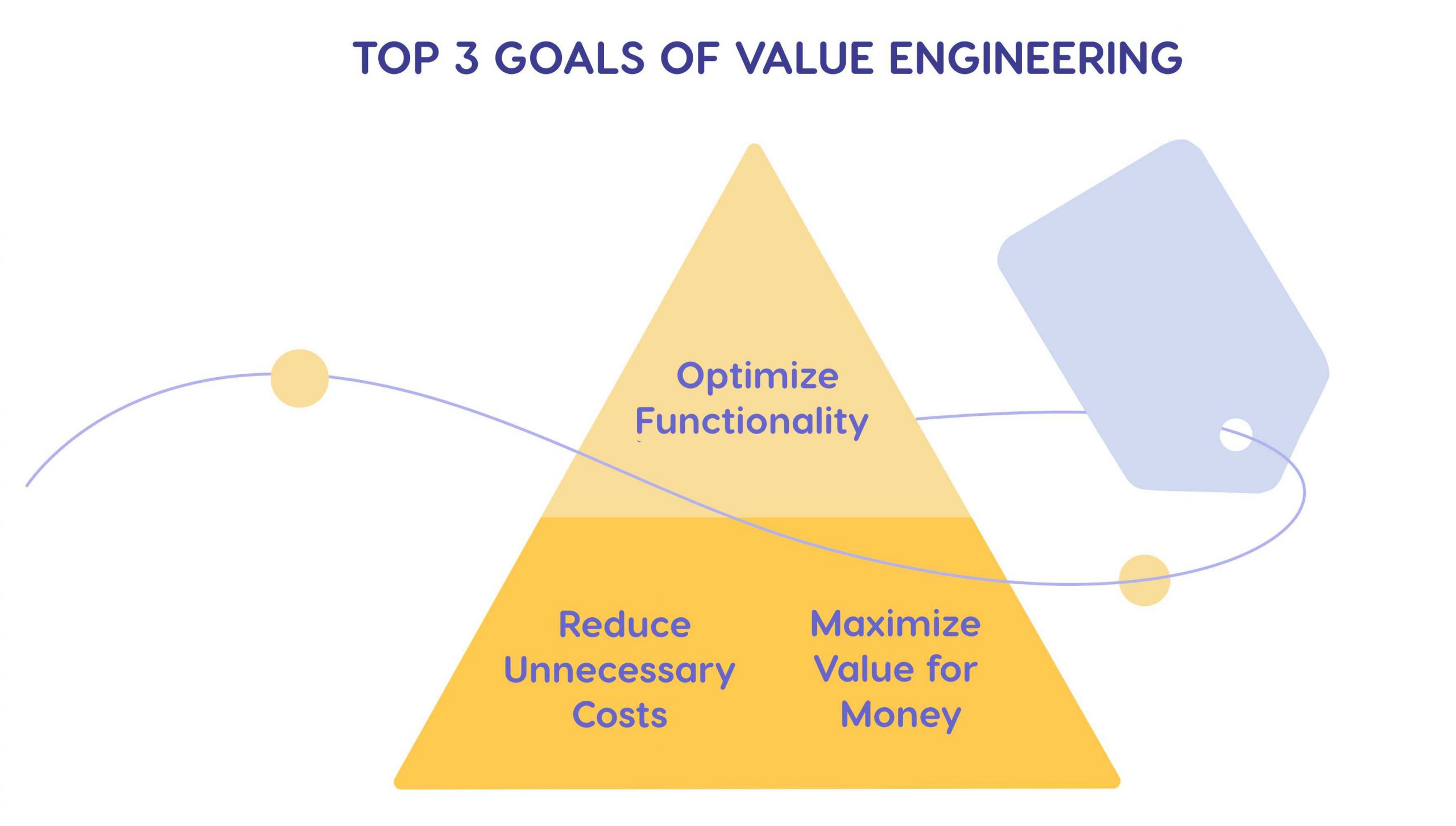

The goals of value engineering

We can distinguish several key value engineering principles and goals.

1. Reducing unnecessary costs.

One of the main goals of value engineering is detecting and eliminating expenses that don’t contribute to delivering value. Instead, the project team should focus on achieving the same or even better results with cheaper alternatives. For example, this may involve replacing imported material with cheaper local alternatives.

2. Optimizing functionality.

The value engineering approach involves the opportunity to detect and remove features or processes that add costs but don’t add value. It aims to deliver the most essential functions of a product or process. For example, when designing a bridge, architects can refuse to add costly decorative elements if the purpose of the bridge is to carry traffic safely.

3. Maximizing value for money invested.

Finally, value engineering aims to achieve the balance between costs and high quality and ensure that every resource invested will return measurable benefits for a project.

Benefits and Importance of Value Engineering in Project Management

- Cost efficiency: Value engineering gives a chance to identify unnecessary costs and eliminate extra expenditures as well as ensure that money is spent on functions that really deliver value to customers.

- Achieving high quality: High quality remains a priority for value engineering, so the project team constantly looks for ways to improve the performance or design of the developed product or process.

- Facilitating innovation and creativity: Value engineering encourages finding innovative approaches and alternative solutions to the traditional materials and ways of working.

- Faster project delivery: Using methods for improving operational efficiency and resource optimization makes it possible to deliver projects earlier.

- Ensuring stakeholder satisfaction: Balancing costs and quality, as well as timely project delivery, contributes to meeting customers’ expectations and ensuring their satisfaction.

- Gaining a competitive advantage: Delivering high-quality products or services, cost optimization, and customer satisfaction gives organizations a competitive advantage.

When to Use Value Engineering in a Project Lifecycle

The right moment for adopting value engineering techniques can make or break it effectiveness. Here are possible stages.

1. Early in the project lifecycle.

This is the optimum stage for conducting value engineering. Why? Because VE will have the biggest impact on a project. At this stage, you can still implement changes more or less seamlessly. Also, you need to decide on material resources you’ll need for project completion, so it’s the optimum time to find suppliers or alternative materials.

2. During the project execution.

Value engineering can be also applied during the project execution, but in this case, its effectiveness will be lower compared to the early stages of the project lifecycle. In addition, changes made at later stages will reduce operational efficiency and may lead to rework and delays.

3. Lesson learned stage.

In some cases, you can apply value engineering as a retrospective analysis at the final stages of project execution. For example, if it were impossible to conduct VE earlier, it could provide you with insights regarding improvement processes for future projects.

The main rule here: the earlier you perform VE, the more value and benefits your project will deliver.

Value Engineering Examples in Project Management Across Industries

For better understanding, let’s consider the value engineering examples in real life across different industries.

Value engineering in aerospace and defense

- Using additive manufacturing: Printing spare parts reduces material waste and accelerates product delivery.

- Leveraging digital twins: Virtual testing before production contributes to shorter product development time.

- Lightweight structure: Replacing some materials with their lightweight alternatives contributes to their weight reduction and reduced fuel consumption.

Read more: New Technology Trends in Aerospace and Defense Industry [2025]

Value engineering in automotive industry

- Material optimization: Using high-strength aluminium instead of steel to reduce weight of vehicles, optimize fuel consumption, and reduce carbon footprint.

- Advanced manufacturing: Using robots for faster production, product defects, and reducing labor costs.

Read more: Key Technology Trends in the Automotive Industry in 2025

Value engineering in construction

- Replacing materials: Builders can use alternative materials that reduce labor time and are more durable.

- Simplifying the design: This may involve reducing unnecessary architectural details.

Value engineering in manufacturing

- Material optimization: Using cheaper alternatives to traditional materials.

- Energy efficiency: Using various technologies to reduce power consumption.

Value engineering in healthcare

- Improving operational efficiency: Adjusting patient flow to reduce waiting times.

- Using energy-efficient lighting: This will contribute to reducing energy costs for hospitals.

- Standardization of room layouts: Building standardized patient rooms to simplify the design and reduce construction costs.

But you may think that some of these measures require costly investments, so what do they have to do with value engineering? If these investments result in delivering value while optimizing costs, they will still count as value engineering. At the same time, not every digital investment will become a part of VE; only those that improve function, quality, and contribute to cost optimization.

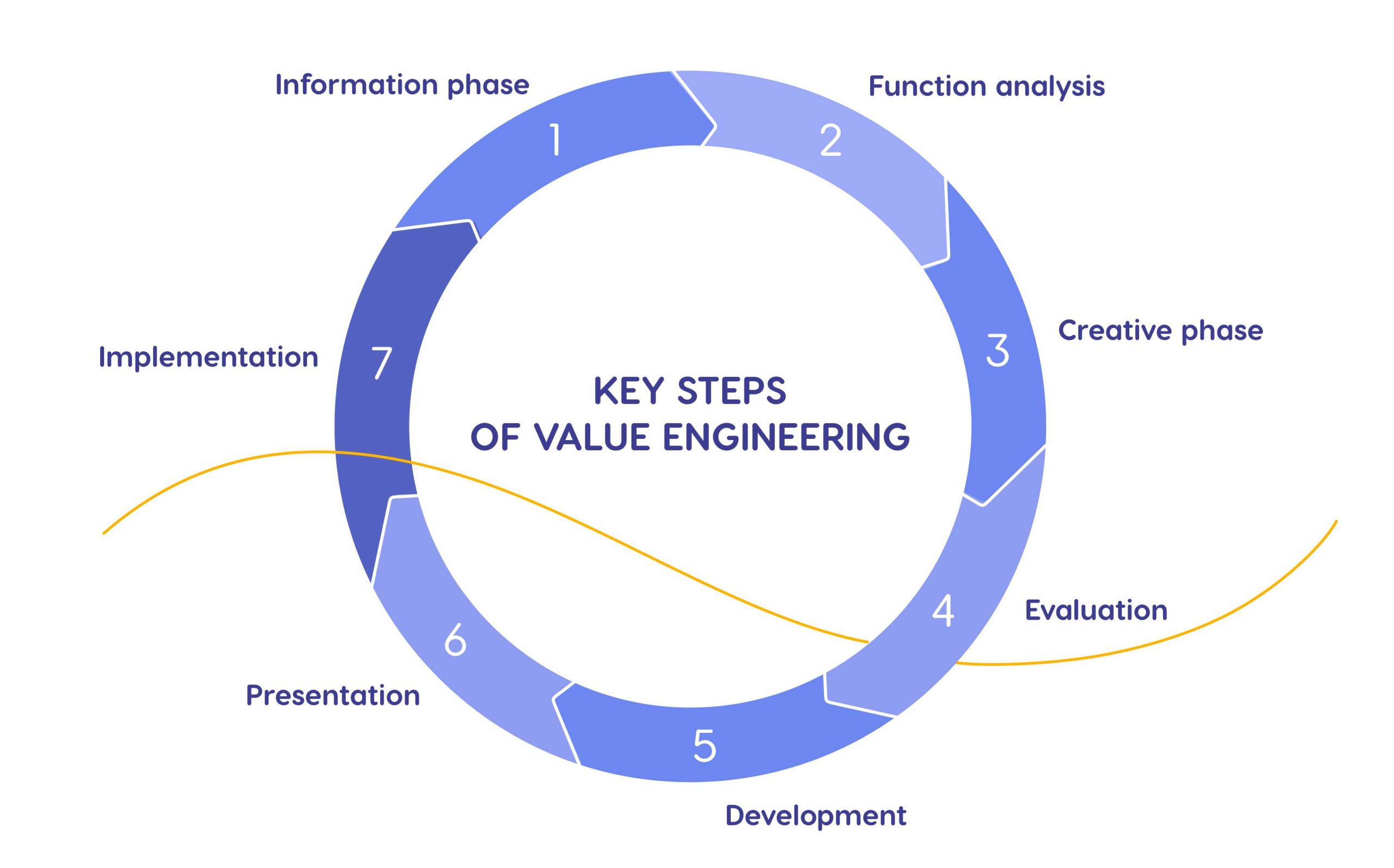

Key Steps in the Value Engineering Process

Let’s now consider the value engineering steps in more detail.

Phase 1. Information phase.

First, you need to assess the situation. This is why it’s essential to gather all project data – scope, functions, costs, constraints, and customer requirements. At this stage, you should also detect potential issues, identify resources required for project completion, and determine which part of the project requires most resources.

Phase 2. Function analysis.

At this stage, you should break down your project into functions or targets to achieve by executing the project. In simple terms, you should give answers to the question: What must it do? It’s also important to identify basic and secondary functions.

Phase 3. Creative phase.

Now, it’s time to analyze each function and find alternative ways to achieve each of them. Use brainstorming techniques and encourage creativity to achieve best results and find best possible alternatives.

Phase 4. Evaluation.

This stage involves the analysis of each of the alternatives found at the creative phase. Team members should list all advantages and disadvantages of the alternative solutions. Also, you should assess feasibility, costs, and impact on performance. As a result, only the most promising alternatives should be selected.

Phase 5. Development.

At the next stage, team members should go deeper and assess each of the alternatives selected at the previous phase. This also involves generating ideas for implementing them, evaluating required costs, specifying technical details, and creating implementation plans. The main goal is to come up with concrete solutions on how to implement the alternatives in the project execution process.

Phase 6. Presentation.

At this stage, team members present their findings to stakeholders and decision-makers. They can use reports, various charts, and comparisons with other alternatives to demonstrate the advantages of solutions they’ve found. It’s also essential to discuss potential challenges related to alternative solutions’ implementation.

Phase 7. Implementation.

And finally comes the implementation phase. If any changes are required, they should be approved and included in the implementation plan before its execution begins.

Effective VE implementation is more than just following the above-mentioned steps. Jump into the next section to find out recommendations that will make value engineering fruitful.

How to Implement Value Engineering Effectively: 5 Tips

Tip 1. Start as early as possible.

In one of the previous sections, we emphasized the benefits of conducting value engineering as early as possible. Optimally, during concept and design phases. In this case, there’s a high chance of achieving maximum value, minimizing costs and resistance to change.

Tip 2. Engage stakeholders.

Involve clients, end users, design team, engineers, and other stakeholders in the value engineering process. The other essential component of successful VE is leadership support. It’s important that all stakeholders agree on the concept of value: cost optimization, increasing performance, sustainability, reducing lead times, etc.

Tip 3. Follow the VE process structure.

To make value engineering a disciplined value-creation methodology, it’s critically important to follow the exact structure that we described in the previous section. Why is it so essential? Because it ensures consistency, creativity, and contributes to achieving desired outcomes in terms of delivering value. Without this structure, there’s a risk that value creation will turn into random cost-cutting.

Tip 4. Encourage creativity.

Creativity is at the heart of the value engineering process, as it allows you to find better ways to achieve the same functions. It allows project teams to find non-conventional solutions that will contribute to generating value. So, you should create a safe environment that will support team members in expressing any ideas without fear of being criticized.

Tip 5. Monitor VE implementation.

To ensure that value engineering will bring the desired results, you should regularly monitor how VE recommendations are integrated into the project. You can also track performance and cost savings to make sure that the expected value will be generated.

Now, it’s time to consider possible challenges you can come across when implementing value engineering.

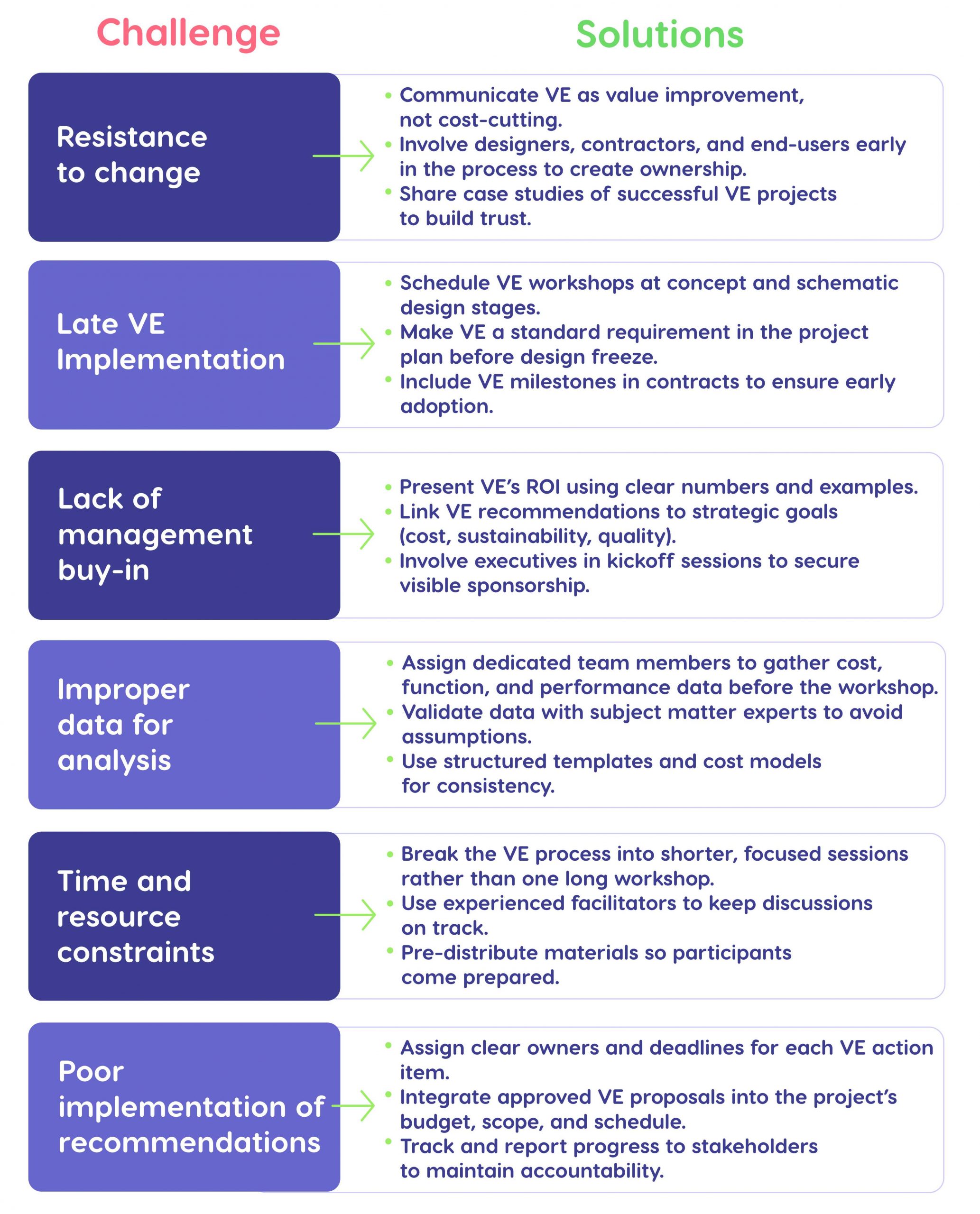

Challenges and Risks of Value Engineering

The difficulties of implementing value engineering methodology are as follows.

1. Resistance to change.

To some stakeholders, value engineering may seem like mere cost-cutting. Designers may consider it a threat to their designs. Other professionals involved in the project execution may think that their work and ideas are underrated. All these factors may lead to resistance to change.

2. Late VE implementation.

Value engineering will be limited in opportunities if it starts after the design is finalized. Late changes may lead to quite the opposite results than cost saving and value delivery. It’s more likely to result in rework that will in turn lead to delays and extra expenditures.

3. A lack of management buy-in.

Some executives may consider the value engineering process as something redundant and not really worth the effort. As a result, they don’t approve the VE ideas and potential improvements, don’t allocate budget for that, and unfortunately lose opportunities.

4. Improper data for initial analysis.

Gathering information is the first step in the value engineering process. But if it’s based on outdated and inaccurate data (reading costs, requirements, etc.), it will be difficult to achieve the intended results of the VE process.

5. Time and resource constraints.

If a project has tight timelines, VE may be considered as extra work that requires time. When it comes to resources, there can be a lack of critical employees who should participate in the value engineering process. As a result, VE can be performed in a superficial manner, which will reduce its effectiveness.

6. Poor implementation of the recommendations.

Last but not least – if there are no employees responsible for following the developed recommendations or they aren’t integrated into the project scope and budget, the results of VE will be far from satisfactory.

Here are some quick tips on how you can address these challenges.

Addressing these challenges will turn value engineering into a consistent and high-impact practice.

Read more: Hiring Extra Employees vs. Adopting a Resource Management Solution: Сhoosing the Right Investment

The effectiveness of value engineering also depends on the right choice of software tools, especially when you work on multiple projects with a shared resource pool. Let’s consider the role of these tools in more detail.

Value Engineering Tools: Epicflow Example

Epicflow is project resource management software designed to meet the needs of complex multi-project environments facing resource constraints. One the core principles of Epicflow – deliver more with less – perfectly resonates with value engineering principles. Here are its capabilities in more detail.

Comprehensive visibility

Epicflow provides a comprehensive visibility into the state of the entire project environment and into each particular project. Also, it serves as a database with all resources involved in multiple projects with all attributes required for optimum resource allocation. Thus, Epicflow provides a single source of truth regarding project statuses, resource availability, and project schedules, which is especially relevant for the environments with multiple complex projects. In addition, you can track budget consumption with Epicflow, which allows you to track costs effectively. Finally, this visibility creates transparency for all project stakeholders and reduces data silos.

Resource optimization

Resource optimization is one of Epicflow’s strong points. The tool optimizes resources in the following ways:

- by ensuring that the right people are available at the right time;

- by planning resource capacity to avoid resource shortages and additional hiring costs;

- by preventing people from overloads and bottlenecks that result in delays and cost overrun.

These measures contribute to more efficient resource utilization across multiple projects and allow companies to deliver more work without increasing the headcount.

Cost optimization

Epicflow optimizes costs by tracking budget consumption, preventing project delays, and optimizing the utilization of available resources across multiple projects.

Early bottleneck detection

Epicflow focuses on bottleneck detection and prevention. Why? Because they can disrupt the workflow of the whole project environment, lead to delays and exceeding the budget. In addition, they hamper people’s productivity and prevent projects from timely delivery. Epicflow’s capacity planning tool can forecast bottlenecks, while its scenario planning functionality, What-if Analysis, helps find optimum ways to resolve them.

Informed decision-making

Making improper management decisions is costly, especially when you manage multiple projects with interdependencies. Epicflow facilitates informed and effective decision-making thanks to its scenario planning functionality. It allows you to run different simulations, predict bottlenecks and risks, or test the best possible solution to address existing issues.

This is only a part of Epicflow’s contribution to the effective value engineering in project management. By the way, Epicflow’s portfolio optimization functionality is underway – it will allow managers to adjust resource allocation to ensure the staffing of projects with the highest business value. Don’t hesitate to contact us to learn more about Epicflow’s value-based portfolio management approach and its transformative impact on your portfolio performance and business outcomes.

Conclusion

Let’s draw some conclusions. Value engineering cannot be considered as a cost-cutting tool. It’s a strategic approach that improves resource efficiency, enhances product functionality, and maximizes the value of projects delivered. Implementing VE empowers business organizations to ensure that every project delivers the highest possible value, achieve competitive advantage and customer satisfaction. AI-powered portfolio management tools facilitate the effectiveness of the value engineering process by optimizing resources, costs, workflows, and decision-making.

Frequently Asked Questions

What is value engineering in a project?

Value engineering (VE) in project management is a structured approach to improving a projects’ value by analyzing functions, costs, and performance. It helps project leaders identify opportunities to reduce unnecessary costs, improve functionality, and enhance product quality while achieving project objectives.

How does value engineering differ from cost-cutting?

Unlike cost-cutting, which often reduces scope and quality, value engineering focuses on maximizing value delivered by projects by balancing cost, performance, and functionality. The main goal of value engineering is achieving better outcomes, not just reducing costs. To understand what is value engineering with example, imagine a bridge project redesigned with lighter materials to reduce costs while maintaining structural integrity

When should value engineering be applied in a project?

Value engineering deliver most benefits when it’s applied at early stages of project execution. In these cases, potential changes are less costly. However, in some cases, it can be reasonable to apply it at later stages, and even use it as experience for future projects.

Who is involved in the value engineering process?

Successful value engineering projects rely on cross-functional teams to evaluate functions, costs, and potential alternatives. They may consist of project managers, engineers, designers, and senior management who will ensure a multi-sided view of potential opportunities and transformations.

What is a good example of value engineering?

An example of value engineering in project management is optimizing the design of a building project. For example, during the planning phase, the project team may analyze the structural system and discover that using prefabricated steel components instead of concrete can reduce construction time, labor costs, and material waste. In turn, this won’t negatively affect the safety and performance standards. On the contrary, this change will improve a project’s value by reducing costs, accelerating delivery, and maintaining high quality.

How does value engineering improve project outcomes?

Value engineering improves project outcomes by ensuring that resources are allocated to functions that deliver the highest value, while minimizing waste, enhancing performance, quality, and return in investment.

What are the basic steps of value engineering?

The phases of value engineering process are as follows: information phase, functional analysis, creative phase, evaluation, development, presentation, and implementation phases.

What tools are used in value engineering?

Value engineering benefits from leveraging resource and portfolio management tools, especially those equipped by predictive capabilities. These tools can help organizations optimize resource utilization, track and optimize costs, forecast bottlenecks and risks.

Can value engineering be used on small projects?

Value engineering can be useful for projects of any size. However, it smaller projects may apply simplified VE processes, while larger projects require more formal VE process and strict following all its stages.

What are common challenges in implementing value engineering?

The challenges of implementing value engineering involve resistance to change, late VE implementation, a lack of senior management buy-in, time and resource constraints, and poor implementation of recommendations.

What are the benefits of value engineering for portfolio management?

Integrating value engineering into project portfolio management allows business organizations to prioritize high-value projects, allocate resources strategically, and improve ROI across the whole portfolio of projects.

What does a value engineer do?

A value engineer is a professional who applies structured methodologies to improve the value of a project and its outcomes. They analyze functions, costs, and performance to detect opportunities for reducing unnecessary costs, improving functionality and quality. Also, they evaluate alternative designs, materials, or processes to reduce expenses and improve performance.