Nowadays, running multiple projects simultaneously is an extremely challenging task. Successful management requires more than just coordination of projects, but also understanding the value that project outcomes will deliver to customers and the organization itself.

Lean project management methodology helps companies address this complexity: it gives managers an opportunity to increase the efficiency of project work, eliminate waste, ensure seamless project execution, and maximize value.

In this article, we’ll explore what lean project management methodology is, how it works, and why it is a must for companies that strive to achieve consistent and value-driven project delivery.

Key Takeaways:

- Lean project management ensures that your project has customer value and is focused on addressing their problems directly.

- The 5 lean principles are defining product value, mapping value stream, creating seamless flow, pulling based on customer needs, and continuous improvement.

- Lean methods include Kanban system, Kaizen culture, PDCA cycle, value stream mapping, just-in-time delivery, and the 5S method.

What Is Lean Project Management?

Lean project management is an approach that follows five core Lean principles, originally developed by Toyota for increasing the efficiency of the manufacturing processes. It is focused on maximizing the end customer value and waste elimination during the project lifecycle. Nowadays, this technique is widely used not only in manufacturing project management; many other industries have adapted it to optimize processes inside their companies.

Lean for project management differs from other methodologies, for example, Agile. On the one hand, they both were created for optimizing processes, but on the other hand, they have different approaches:

- Agile is perfectly suited for dynamic environments, like software development, and is focused on flexibility and adjusting to changes;

- Lean appeared in manufacturing, and its main purpose is to cut down on waste to make processes more efficient.

Now that we understand the basics, let’s take a closer look at lean project management principles.

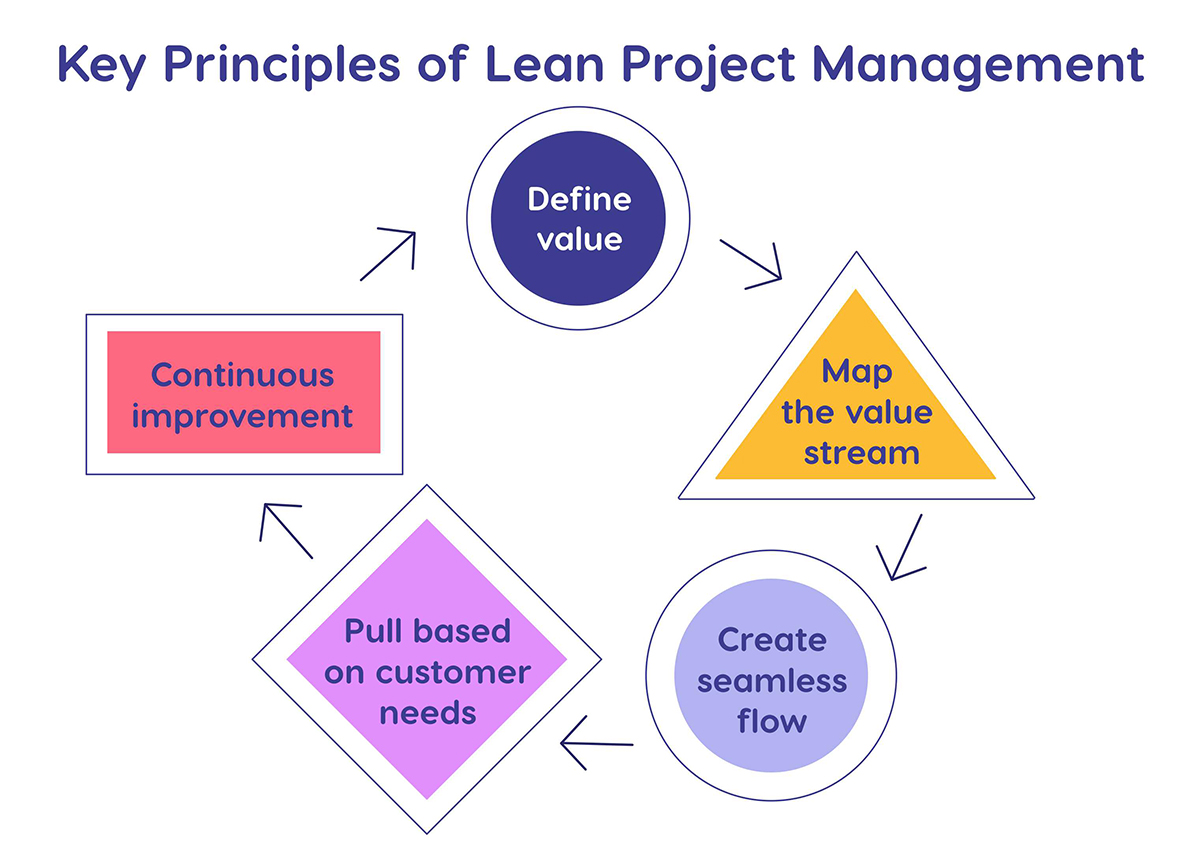

5 Key Principles of Lean Project Management

Originally, the five principles of lean project management were described in 1997 by the Lean Enterprise Institute in a book called “Lean Thinking”. We can imagine them as steps of defining customers’ problems and finding proper solutions to solve them. So, let’s consider these steps in more detail.

1. Define value.

The process starts from defining the value of your product or project for end customers. It is about diving deep into customers’ pain points and ensuring that your product/service directly addresses them. It can be some unique feature, benefit, combination of different functions in one solution, etc.

After defining customer value, project managers will know exactly which requirements a project should meet to deliver a unique selling proposition (USP) to solve customers’ problems and reach the best outcomes.

2. Map the value stream.

Value stream mapping (VSM) is the next step in lean project management, which is about creating a detailed plan from idea to project delivery. It uses diagrams to visualize the sequence of steps that must be done, including approvals, documentation, reworks, waiting time, etc. While doing it, project managers and executives can highlight potential roadblocks in the workflow and project management risks as well as take action to prevent them.

3. Create seamless flow.

The next step after creating a map and removing obvious obstacles is to create a steady workflow, which ensures that work will move from one stage to another without delays and bottlenecks.

To create efficient flows, project managers should:

- Prioritize tasks and projects according to their urgency and importance for the company’s strategic goals;

- Use workload management software to balance resources and avoid conflicts;

- Automate repetitive tasks as much as possible to decrease risks of human factor mistakes and increase productivity.

Project management software tools like Epicflow with predictive analytics capabilities help managers and executives prioritize tasks and projects properly and allocate resources to the most important projects in line with their capacity, availability, and skills. The combination of the lean project management principle with the right software is the key to process efficiency, optimal resource utilization, and achieving expected results. Contact our experts to investigate all capabilities of Epicflow.

4. Pull based on customer needs.

In this situation, “pull” means doing work when it’s really needed, instead of doing it in advance, just in case. For example, in manufacturing projects, it can be producing some goods in response to customers’ demand. When it comes to project work in general, it can be working on the highest-priority tasks for the moment. Also, this is about aligning demand with available capacity. This prevents poor resource utilization, when you don’t have enough resources for doing really important tasks, and overproduction, when project teams work on something that won’t deliver value for the customer.

5. Continuous improvement.

Lean project management is about long-lasting improvements and growth. It is the last principle, which involves seeking for perfection through analyzing past experience, effective problem-solving, open communication, and learning from feedback.

Lean Project Management Methods and Approach

Lean project management provides several useful value-oriented project management frameworks that you can integrate into your workflow for greater efficiency.

1. Kanban boards.

Kanban boards are one of the most popular and recognizable methods in lean project management. It involves using the actual or, most often, virtual boards that divide work into different columns, so everyone is aware of the project’s progress, for example:

- “To do”

- “In progress”

- “On review”

- “Done”

Also, project managers can tag tasks and projects with specific colored labels to highlight their urgency and priority. This structured approach keeps tasks’ statuses clear and shows real-time progress, which is necessary for every project work but especially if you are managing multiple projects simultaneously.

2. Kaizen.

“Kaizen” is a Japanese word that means continuous improvement and growth. It encourages improvement through small, consecutive steps, which lead to significant project success over time. Project teams constantly review workflows, detect bottlenecks, and fix them instead of waiting for a major review, so that time isn’t wasted and can be spent on more important work. Therefore, overall efficiency is growing and limited resources are used optimally.

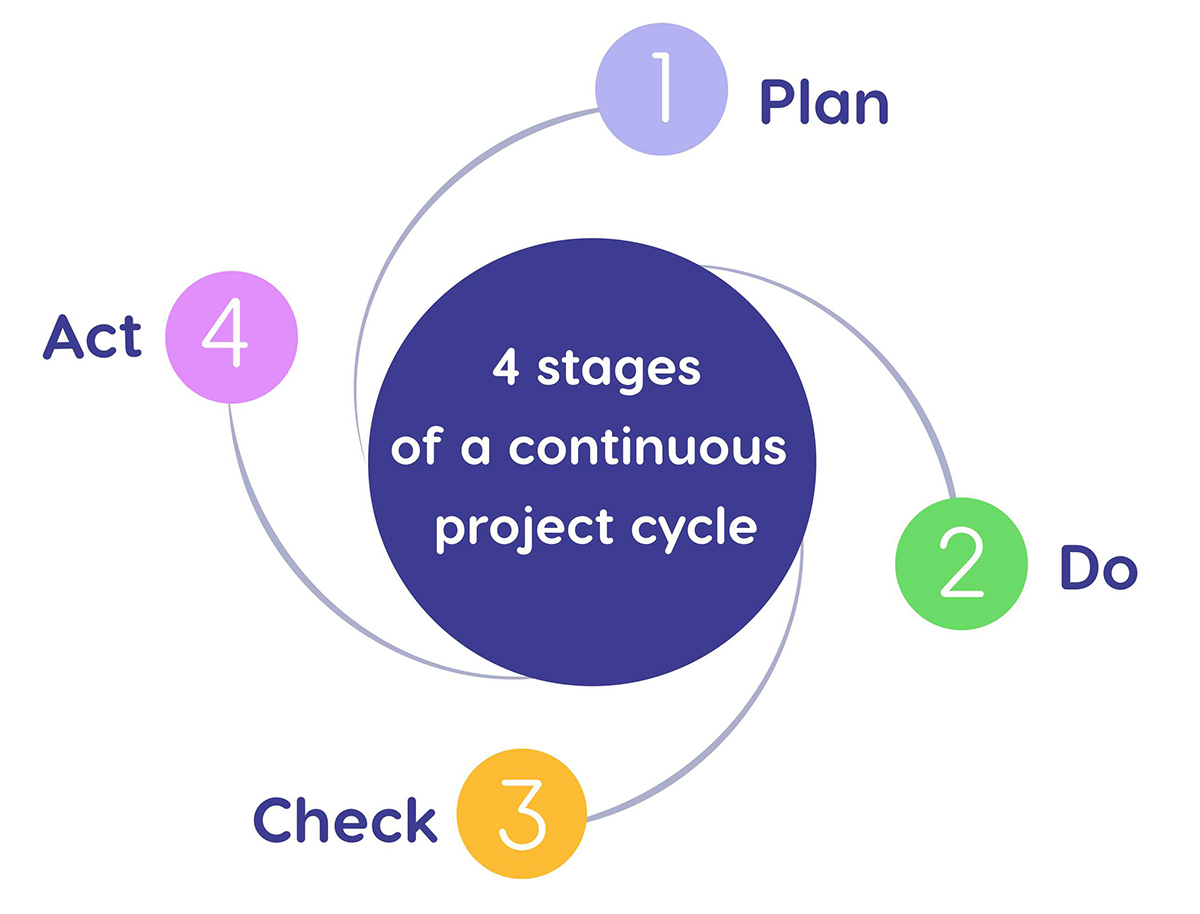

3. Plan-Do-Check-Act cycle (PDCA).

It is a structured approach that is based on 4 stages of a continuous project cycle:

- Plan: defining the customer’s problem, setting SMART project goals, and identifying strategy for proper planning and scheduling;

- Do: piloting small-scale implementation to test your plan with minimum project risks;

- Check: reviewing the results of the test according to strategy goals;

- Act: if everything is fine and works well, continue implementing it on a larger scale; if it isn’t, adjust and rerun the PDCA cycle.

It gives an opportunity for structured experimentation during the project lifecycle and allows for continuous growth and learning, supporting Kaizen and other lean principles in project management.

4. Value stream mapping (VSM).

As we’ve already discussed, value stream mapping is a lean visual project management tool that stands for a process of creating a diagram of every step required to deliver a project successfully. It allows you to spot less important work early and avoid wasting resources, using them efficiently during project execution. The main points here are:

- Identifying every step from customer’s problem to product delivery;

- Spotting the most valuable and non-valuable parts;

- Detecting the points where work can stack or slow down.

5. Just-In-Time (JIT) delivery.

This lean project management approach ensures that your team is working only on needed tasks, at the exact time, avoiding unnecessary work, e.g., developing any extra features that go beyond the requested functionality. It allows you to:

- Eliminate waste;

- Reduce resource overbooking;

- Improve efficiency and success rates.

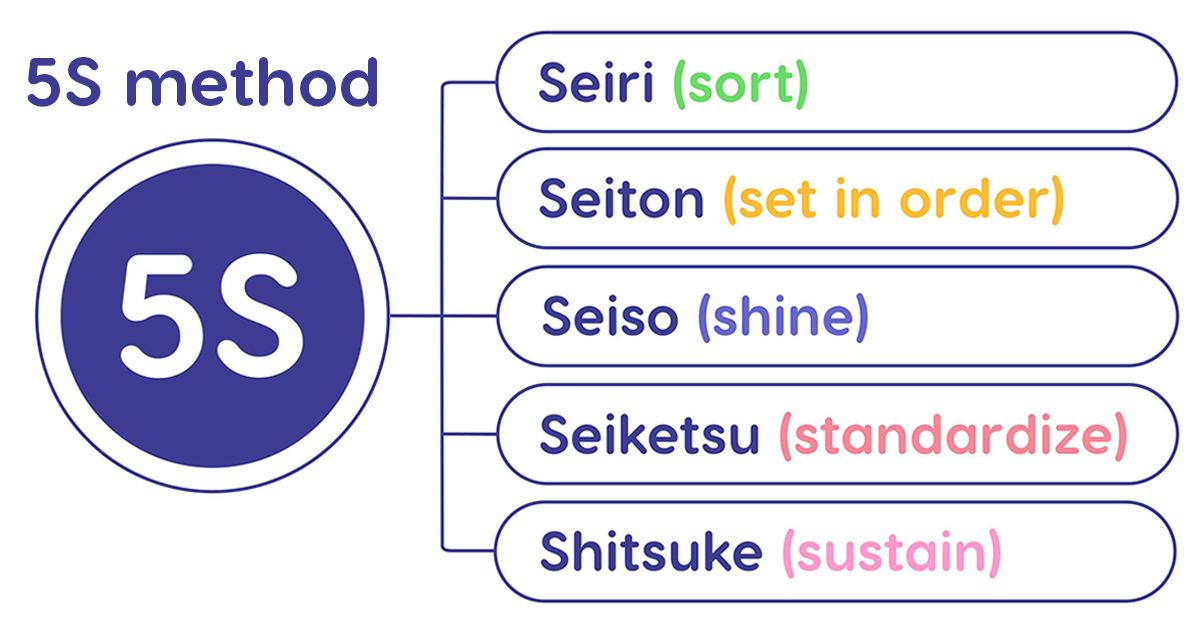

6. 5S method.

This method originally comes from the Japanese automotive industry, was developed also by Toyota, and is now widely used in other industries. It stands for five principles of creating clear and ready-to-work environments. So, what are these 5S for project management?

- Seiri (sort): eliminate unnecessary and inefficient processes;

- Seiton (set in order): organize everything logically after sorting;

- Seiso (shine): keep workspace clean and structured;

- Seiketsu (standardize): create working standards so everyone can follow the same rules;

- Shitsuke (sustain): continuously apply new approaches.

Read more: Engineering Project Management: The Essential Guide

Benefits of Lean Project Management

Now, when we know more about the lean project management role and its key principles, let’s dwell upon the advantages that you gain by using this approach.

1. Minimizing inefficiencies and waste.

By implementing lean project management into your workflows, you’ll be able to eliminate inefficiencies before they lead to wasting resources, increased costs, or delays. This refers to both reducing waste of materials and human resources.

2. Growth of efficiency.

With reducing waste and inefficiencies comes constant growth of productivity and efficiency. By using lean project management methods like 5S or other principles, you’ll pay more attention to customer needs and avoid work that brings no value for them or your company’s strategic goals. Moreover, project teams will focus on the most important projects, which will maximize value for an organization.

3. Higher customer satisfaction.

When a project outcome is focused on addressing customers’ pain points and delivering value, it will make your relationships with the clients stronger, increasing customer loyalty and making you stand out from competitors.

3. Reduced costs and higher revenue.

When you avoid wasted effort and resources, you can deliver more with the same resources. It saves money and time, which can be spent on more important initiatives or used as a buffer to protect a project from delays. Therefore, this point is not only about saving money but also about increasing ROI and overall revenue.

4. Continuous improvement.

Delivering product value isn’t an easy task to do, but success is impossible without learning and gaining new experience. An ongoing feedback loop is vital in lean project management because it allows for collaboration in problem solving, sharing knowledge across all team members, and growing together.

How to Implement Lean Project Management

Let’s now consider the step-by-step roadmap of actions you should take to implement a lean approach to project management in your company.

1. Understand customers’ requirements.

Identify what matters most to your customers and stakeholders. To do it properly, you should foster open communication and gather feedback to make sure that the project outcomes will deliver value to them. Run regular discussions with stakeholders to align expectations and determine project requirements as well as develop precise success criteria to rely on (e.g., it can be anything from aesthetic user interface to reducing costs).

2. Map the project management process.

Create the map of the project lifecycle from user request to product delivery. Determine what resources you’ll need to deliver the tasks. This will help you identify resource and skill shortages and efficiently reallocate them from less important processes without blocking any initiative.

3. Identify and eliminate waste.

As soon as the process becomes visible, it is time to spot where resources are wasted. Look over 7 waste categories aligned with lean project management principles:

- Overproduction: delivering redundant products or features;

- Overprocessing: a too complex process of execution or delivery that will cost more than revenue gained;

- Transport: unnecessary or unoptimized movements of products and parts. For example, manual data exporting to different spreadsheets instead of keeping it in one place or automatic integrations;

- Waiting: one process blocks another, waiting for approvals, supply chain management, waiting for a colleague to complete the work, etc.

- Motion: unnecessary movement of people or their attention while working;

- Inventory: it is about work that should’ve been done but has not delivered customer value yet because it’s waiting to be used or processed;

- Correction: finding defects and reworking because of fixing them.

Bottlenecks are the other source of waste – they lead to waiting and delays as well as inefficient use of resources. You can use predictive software to forecast bottlenecks and prevent them before they disrupt the workflows.

4. Redesign a flow.

Once you’ve recognized the waste and bottlenecks, the next step is to plan a workflow that will be seamless and simple enough for your employees to follow so that the risk of disruptions and inefficiencies is minimized. You can do it with Kanban boards or AI-powered resource management tools that immediately prioritize tasks, select available resources, and help assign them to the right tasks.

5. Establish pull.

Avoid resource overload and double booking by bridging resource demand with available supply – i.e., assigning resources to projects and tasks in line with their available capacity. Capacity planning software allows you to predict capacity and workloads and to timely detect potential overloads and prevent them.

6. Foster a culture of Kaizen.

With the help of lean frameworks, like the PDCA cycle discussed before or the 5S method, you can ensure continuous improvement. To foster the culture of Kaizen, you can run scenarios before making decisions; this will help you select the optimum ones without putting your workflows at risk. Also, you should analyze the lessons learned after completing projects, run discussions on what worked well and what didn’t, and take this experience into account for future work.

Lean Project Management Examples and Case Studies

Let’s now take a look at how lean project management influences different industries.

1. Software development projects.

According to the article, lean IT project management shows its positive effect on software development and IT companies. It is a highly competitive area with constant pressure of high stakes and evolving technologies, where lean project management principles like constant improvement help to effectively fit in tight deadlines and deliver the most successful projects within the budget. Moreover, eliminating waste makes stakeholders and clients satisfied, and companies are more likely to gain more traction in the market.

2. Manufacturing projects.

Lean project management takes its origin in manufacturing which explains its 100% suitability for this industry. By waste elimination and creating a smooth delivery process, these companies can reduce costs and deliver more quality products with fewer defects. Also, lean project management for engineers helps them to increase productivity and create more with the same effort.

3. Telecom projects.

The telecom industry is another extremely vulnerable field where lean methodology plays a crucial role for successful project execution. Often telecom companies struggle with uncertainties, wrong prioritization, workforce and skill gaps, complex infrastructure, etc. Lean principles streamline processes of telecom project management, make them more efficient, reduce bottlenecks and waste of scarce resources, helping project managers keep initiatives on track and facilitate their successful delivery.

Lean Project Management Tools

Lean project management principles work well when combined with robust project management tools, especially when you work on multiple projects and have limited resources. Epicflow is an AI-powered multi-project management software that is designed to solve the common challenges companies may struggle with while handling a huge portfolio of concurrent projects. It supports lean project management principles with the following capabilities:

- Eliminating bottlenecks and improving flow: Epicflow detects bottlenecks across projects, helps eliminate and prevent them in the future, which leads to smoother project flow, fewer delays, and faster lead times.

- Optimizing resource utilization: Capacity forecasting, intelligent resource allocation, and workload balancing ensure optimal resource utilization and efficiency.

- Providing real-time data analytics: Project leaders and team members can learn from performance data, which facilitates continuous improvement.

- Reducing work in progress: Epicflow prioritizes tasks and projects so that the team can focus on the most important ones to reduce multitasking and increase efficiency;

- Facilitating value delivery: Epicflow helps prioritize and deliver projects with the highest business value.

Therefore, Epicflow facilitates flow, value delivery, resource efficiency, and continuous improvements, which support lean project management principles. If you want to see how this works in practice, don’t hesitate to book a call with our experts and discover other benefits of Epicflow multi-project management software.

Conclusion

Many organizations, especially multi-project ones, are struggling to deliver maximum value with minimum waste, and the usage of lean project management methodology is a good way to make this process easier. It’s focused on addressing customers’ pain points, increasing the efficiency of processes, and minimizing waste, which makes this approach valuable for both clients and the organization.

How to implement lean project management principles into your workflows?

- Understand what your customers need and what the main problem is.

- Create the map of the delivery process.

- Spot bottlenecks and inefficiencies and find out how to avoid them.

- Redesign the flow without identified problems.

- Establish work pull.

- Improve continuously, learning from mistakes and feedback.

Hope that now you understand the main lean project management principles and their importance for smooth and efficient workflows and product value delivery.

Frequently Asked Questions

What is lean system in project management?

Lean methodology in project management is a popular approach based on product value delivery to end customers. It is focused on clients’ problems and helps companies find ways to develop the right solution that will cover all pain points.

What are the 5 principles of lean project management?

The main principles of lean project management are:

- Defining product value.

- Mapping the value stream.

- Creating seamless flow.

- Pulling work based on customer needs.

- Continuous improvement.

How does lean project management work?

It works by analyzing the customers’ needs and problems, creating a map of project execution, eliminating waste, creating flawless workflow, and finally continuously improving based on data and feedback.

When to use lean project management?

You should use lean methodology when you want to optimize processes inside the organization, avoid wasted effort, achieve better outcomes, and strengthen relationships with clients.